|

| |

India is the largest democracy, fourth largest economy (in terms of purchasing power parity) and the tenth most industrialised nation in the world. Triggered by the opening of the economy in 1991 and backed by strong year on year near to two digit Economic Growth, India is becoming an abode for Foreign Investments, a centre for Skilled Manpower and a nursery for New Businesses.

The Government of India realised the role of infrastructure in such a developing economy and has over the years executed infrastructure projects worth several crores. After the opening of the sector to private players the sector’s contribution to the GDP has risen from 3.5% in 1996-97 to 8.5% in 2006.

By its public-private partnerships, the Government has provided an area of growth for infrastructure companies and has fast tracked the execution of its projects. This public-private partnership today also provides various investment options by way of tax-saving Infrastructure Bonds.

Tapi Infrastructure Limited in partnership with various State Governments has executed a wide array of infrastructure projects and has an expertise in areas of Water Supply, Irrigation, Water Treatment Plants, Roads and Bridges. |

| |

| Company Information |

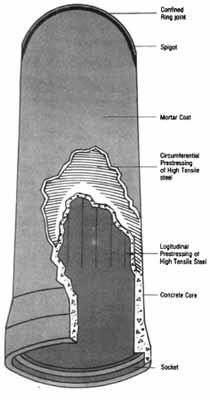

Tapi Prestressed products private Ltd.(Now Tapi Prestressed products Ltd.)was established and commissioned in 1987 with Technical Collaboration wiht M/s.Zubin of West Germany for manufacturing of World Standard P.S.C. Pipes in India. A Mechaanical workshop was simultaneously established for production of specialized equipments required for manufacturing for P.S.C. pipes. At present we are manufacturing P.S.C. Pipes to I.S.I. Specification of diameters ranging from 300 mm to 1700 mm with hydraulic pressure from 4 kg/cm2 to 32 kg/cm2.

The Company also undertakes Turnkey Projects of Water Supply & Lift Irrigation Schemes including Headworks, Pumping Machinery and other allied works.The company has gained good reputation for all round excellance of modern technology, stringent quality control, timely execution and continuous research and develpment. |

| |

| The Design |

| |

|

|

| The basic principle is to adopt wall thickness, longitudinal & circumferential prestresses to ensure freedom from tensile stresses in the core pipe under the most severe combination of sustained internal pressure and external loads likely to occure in service. The design is based on the following factors: |

| |

Self weight of pipe. |

| |

Water hammer pressure. |

| |

Interanl pressure. |

| |

Bedding and backfill. |

| |

Traffic wheel loads. |

|

| jont assembly design is related to clearance between joint surfaces, tolerances to pipe ends, rubber ring size, rubber hardness, creep of rubber and friction of rubber on concrete. |

| |

|

|

| |

| DIMENSIONS AND WEIGHTS OF PIPE |

| |

| |

Dia.

in (mm.) |

Effective length

in (mtrs.) |

Approximate

weight per pipe

in (M.T) |

| 300 |

5.000 |

0.88 |

| 350 |

5.000 |

0.98 |

| 400 |

5.000 |

1.20 |

| 450 |

5.000 |

1.34 |

| 500 |

5.000 |

1.48 |

| 600 |

5.000 |

1.73 |

| 700 |

5.000 |

1.98 |

| 800 |

5.000 |

2.42 |

| 900 |

5.000 |

3.09 |

| 1000 |

5.000 |

3.73 |

| 1100 |

5.000 |

4.16 |

| 1200 |

5.000 |

5.20 |

| 1300 |

5.000 |

6.00 |

| 1400 |

5.000 |

6.60 |

| 1500 |

5.000 |

7.33 |

| 1600 |

5.000 |

8.56 |

| 1700 |

5.000 |

8.96 |

|

|

| |

|